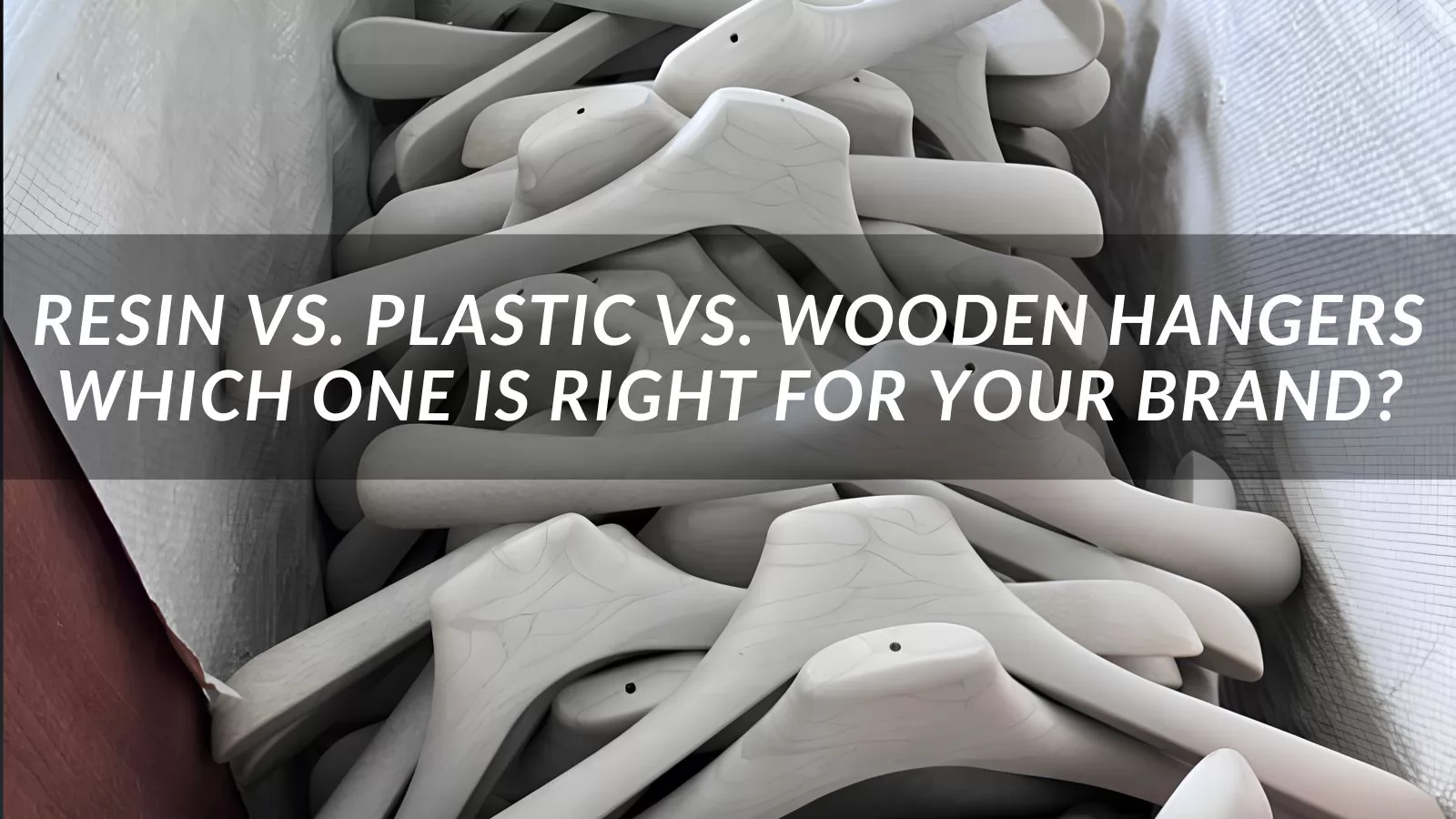

Choosing the right garment hanger isn’t just about function — it’s a strategic brand decision. The hanger your clothes hang on influences how customers perceive quality, care, and value.

As a trusted hanger manufacturer with over a decade of experience in plastic and resin production, EISHO Resin Hangers has helped fashion brands worldwide upgrade their retail presentation. We’ve seen the shift: more boutiques, multi-brand showrooms, and premium labels are switching from plastic and wood to resin hangers — and for good reasons.

In this comprehensive guide, we compare the three most common hanger materials across five critical dimensions:

By the end, you’ll know exactly which hanger type aligns with your brand’s image, budget, and long-term goals.

The last thing you want is a hanger failing in-store or during a photo shoot. Let’s examine how each material holds up under real-world conditions.

Resin hangers are made from solid synthetic resins like epoxy or polyester, poured into precision molds. The result? A dense, impact-resistant hanger that won’t crack, warp, or deform.

Ideal for heavy coats, wedding dresses, and high-value collections.

Common in fast fashion, plastic hangers are cheap to produce but fail in durability.

Best for short-term use, but not for premium branding.

Wood offers natural elegance, but only if properly sourced and treated.

Heavy weight increases shipping costs — a hidden expense.

Your hanger should enhance, not distract from, your garments. Let’s see how each material performs in retail and photography settings.

Resin allows for unmatched design flexibility. It can mimic:

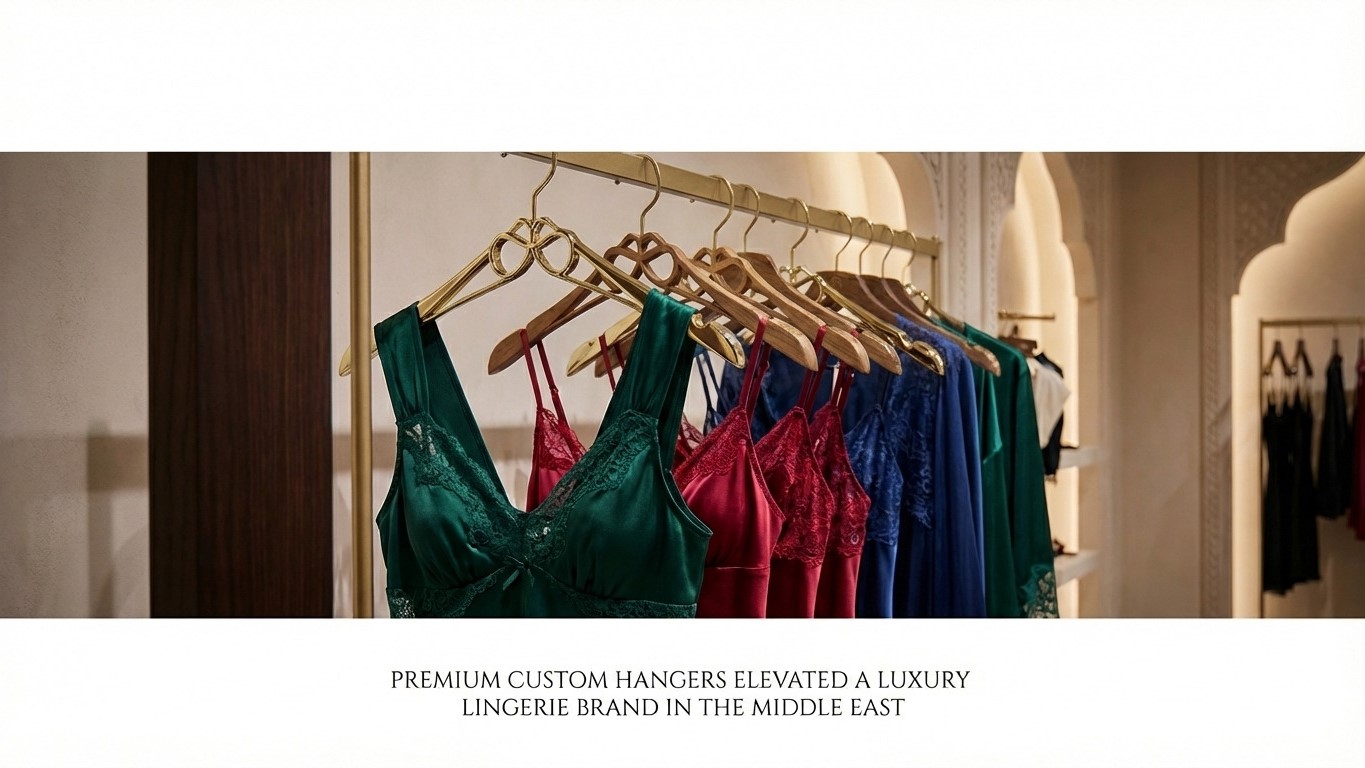

Available in rich, consistent colors: Black, White, Brown, Emerald Green, Burgundy, Soft Pink, and custom Pantone matches.

Seamless, one-piece molding means no visible parting lines — a clean, gallery-like presentation.

Used by flagship stores and bridal studios for their “museum-quality” display.

Even high-quality plastic has a glossy, mass-produced appearance.

Fine for backroom use, but undermines brand value on the sales floor.

Wood brings organic charm, ideal for heritage or artisanal brands.

Best for niche, storytelling-driven brands.

Let’s break down the real cost — not just per unit, but per year of use.

| Material | Unit Cost | MOQ | Lifespan |

|---|---|---|---|

| Resin Hangers | Medium | 50–2,000 pcs (design-dependent) | 3–5 years+ |

| Plastic Hangers | Low | 3,000–10,000 pcs | 6–18 months |

| Wooden Hangers | High | 1,000–5,000 pcs | 2–4 years |

Key Insight: While resin hangers have a higher upfront cost than plastic, their longevity and reusability make them more cost-effective over time.

And here’s the game-changer: our in-stock resin hanger designs have MOQ as low as 50 pieces. Perfect for:

Greenwashing won’t cut it anymore. Let’s assess each material honestly.

Most plastic hangers are made from PP or PS — neither is easily recyclable in practice.

Deforestation, chemical treatments, and transportation emissions reduce the eco-balance.

While synthetic, resin hangers win on lifecycle impact.

Durability is the first step toward sustainability.

Your hanger should reflect your brand identity — not look generic.

Thanks to advanced mold-making and coloring, resin hangers offer unmatched customization:

Example: A bridal brand requested a semi-transparent white hanger with a gold-foiled logo — now used in all their flagship stores.

Custom molds are expensive and require high MOQ (5K–10K). Color matching is often inconsistent.

You can laser-engrave logos, but color and shape customization is nearly impossible.

Here’s a quick decision guide:

| Brand Type | Recommended Hanger | Why? |

|---|---|---|

| Fast Fashion / High Volume | Plastic | Low cost, disposable model |

| Luxury / Designer / Bridal | Resin | Premium look, durable, customizable, brand-aligned |

| Heritage / Craft-Focused | Wood | Authentic, traditional appeal |

| Multi-Brand Showroom / Retail Chain | Resin | Uniform appearance, color-matching, no cracking |

For most mid-to-high-end brands, resin hangers offer the best balance of aesthetics, durability, and value.

We’re not just another supplier. We’re a plastic hanger manufacturer that evolved into premium resin production — and that gives us unique advantages.

With over 10 years in injection molding, we understand hanger structure, balance, and mold flow. This means:

We’ve adapted our proven QC system from plastic to resin, ensuring:

Resin materials are part of the broader plastic supply chain. Our long-term supplier relationships ensure stable quality and competitive pricing.

No need to order thousands. MOQ from 50 pcs for in-stock designs. Free samples shipped in 3–5 days.

We’ve helped hundreds of brands upgrade from plastic to resin — for flagship stores, bridal lines, and seasonal campaigns.